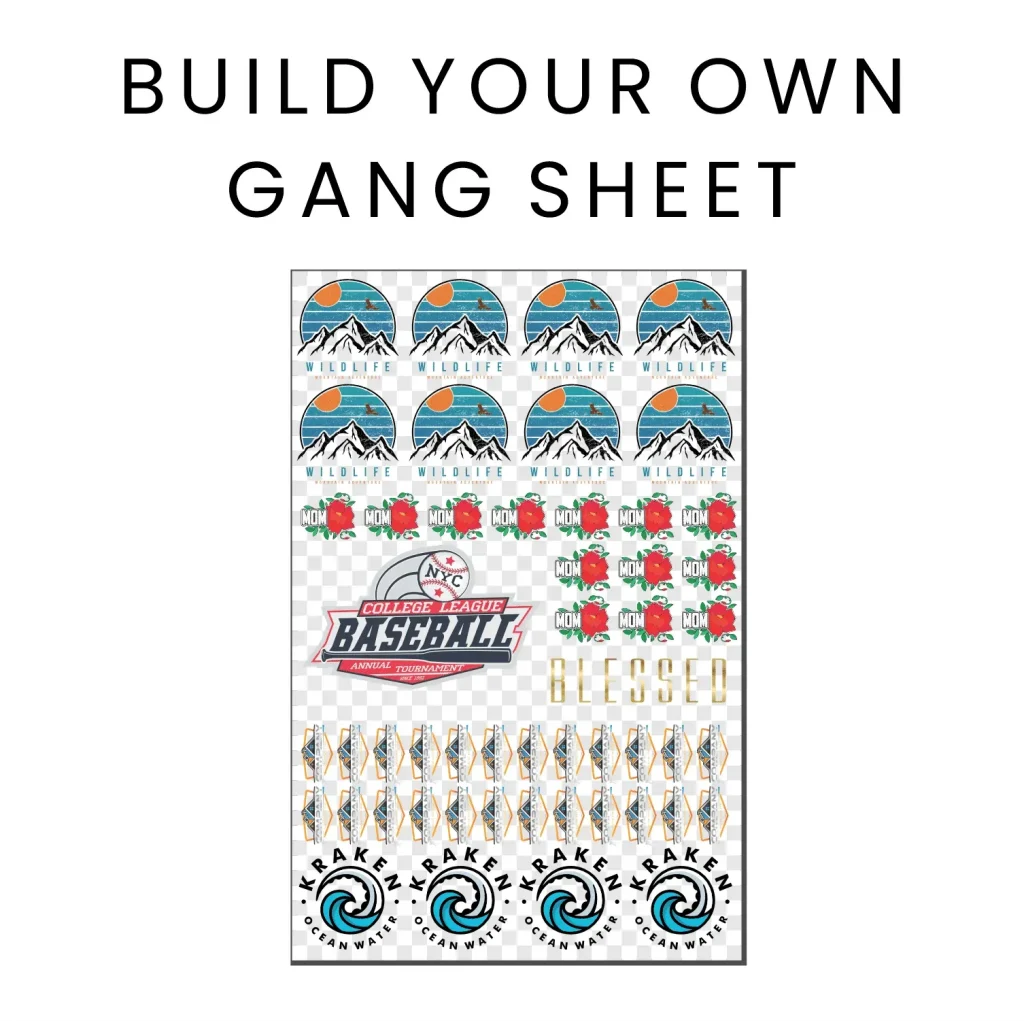

If you’re venturing into the world of custom printing, the **DTF Gangsheet Builder** is an essential tool that promises to transform your printing process. This innovative software streamlines the DTF printing process, allowing for stunning designs to be created effortlessly. In this detailed DTF printing tutorial, you’ll learn the ins and outs of effectively utilizing the Gangsheet Builder, covering everything from DTF software setup to heat press application. The DTF Gangsheet Builder not only enhances efficiency but also yields vibrant, durable prints that cater to both amateur and professional printers alike. Prepare to boost your DTF design preparation skills, as this guide will lead you through a comprehensive journey toward achieving print perfection.

In the realm of custom textile printing, the Direct-to-Film (DTF) method has emerged as a game changer, making the **DTF Gangsheet Builder** a vital asset for any printing enthusiast. This powerful tool facilitates the efficient layout and printing of designs on sheets, maximizing resources while ensuring high-quality output. As you navigate the DTF printing landscape, understanding the nuances of software setup, design arrangement, and application techniques will be crucial. Whether you’re tackling a single design or multiple layouts, mastering this gangsheet approach will elevate your printing capabilities. Join us as we explore every facet of this remarkable printing process, ensuring that your creations resonate with quality and vibrancy.

Introduction to DTF Printing Technology

Direct-to-Film (DTF) printing technology is at the forefront of modern printing methods, particularly in custom apparel. Unlike traditional methods, DTF allows for intricate designs and a wider variety of fabric compatibility, delivering sharp images and vibrant colors. This innovative process has become essential for businesses aiming to succeed in a competitive market. DTF printing combines efficiency and quality, making it a go-to choice for both small-scale entrepreneurs and larger manufacturing operations.

As the demand for customization rises, understanding DTF printing and its applications becomes paramount. This technology offers simpler processes and reduced waste compared to other printing techniques, positioning it as a breakthrough in the print technology landscape. By utilizing a specialized film that transfers the design directly onto fabric, businesses can save both time and resources while achieving outstanding results.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how is it used in DTF printing?

The DTF Gangsheet Builder is a specialized software tool used in Direct-to-Film (DTF) printing to create organized layouts of multiple designs on a single film sheet. It helps streamline the printing process by maximizing ink usage and minimizing waste, allowing users to achieve vibrant prints efficiently.

How do I set up DTF software before using the DTF Gangsheet Builder?

Before using the DTF Gangsheet Builder, ensure your DTF printer software is up-to-date. Install the software, then familiarize yourself with its interface through tutorial modes or user manuals provided. This initial setup is crucial for a smooth DTF printing experience.

What are the key steps in DTF design preparation using the Gangsheet Builder?

In DTF design preparation, start by creating or uploading high-resolution designs (300 DPI) into the Gangsheet Builder. Utilize its tools to carefully size and position your designs according to the fabric dimensions, ensuring optimal layout for printing.

What color management techniques should I follow when using the DTF Gangsheet Builder?

To maintain color accuracy in DTF printing, select appropriate ICC color profiles for your printer and ink type. Regular calibration of your printer is essential to ensure consistent color representation throughout your print runs.

What is the recommended heat press application process for DTF prints?

For DTF prints, position the cured transfer accurately on the garment and apply it using a heat press. Generally, a temperature of around 160°C for 15-20 seconds is recommended, but always refer to the manufacturer’s instructions specific to the film type used.

Can the DTF Gangsheet Builder help optimize printing efficiency?

Yes, the DTF Gangsheet Builder enhances printing efficiency by allowing users to arrange multiple designs on one sheet, reducing wasted ink and film. Its intuitive layout helps users design prints that maximize fabric coverage while minimizing production time.

| Key Point | |

|---|---|

| What is DTF Printing? | DTF allows high-quality fabric prints using a special film transfer method, known for its efficiency and vibrant colors. |

| Step 1: Software Setup | Install the latest DTF printer software and familiarize yourself with its interface. |

| Step 2: Design Preparation | Use high-resolution images (300 DPI) and adjust sizes in the Gangsheet Builder. |

| Step 3: Gangsheet Configuration | Arrange multiple designs on one sheet efficiently while managing margins. |

| Step 4: Color Management | Use correct ICC profiles and calibrate your printer for true color representation. |

| Step 5: Printing | Conduct test prints and be aware of film types for best results. |

| Step 6: Curing Your Prints | Cure prints using a heat press with the right temperature and time. |

| Step 7: Application to Fabric | Accurately position and apply transfers using a heat press according to specifications. |

Summary

The DTF Gangsheet Builder is a transformative tool for custom printing that enhances both the efficiency and quality of your prints. By following the outlined steps—from software setup and design preparation to the final application on fabric—you can achieve vibrant, professional results. This process not only saves time but also optimizes material usage, making it ideal for businesses of all sizes. As you navigate through the world of DTF printing, leveraging resources and engaging with the community can greatly bolster your skills and keep you updated with the latest trends. Happy printing with the DTF Gangsheet Builder!