DIY UV DTF printing is transforming the landscape of custom apparel printing and home decor design. This modern approach utilizes advanced UV DTF printing techniques to create vibrant and durable designs that can be applied to a multitude of surfaces, ranging from textiles to wood and glass. With the surge of affordability in UV printers, DIY enthusiasts and small businesses are seizing the opportunity to personalize their crafts like never before. In this guide, we’ll delve into the essentials of direct to film printing, explore tips for mastering the craft, and inspire new DIY crafting projects that will elevate your creative game. Get ready to unlock endless possibilities with DIY UV DTF printing and bring your unique vision to life!

When it comes to innovative crafting methods, there are few as exciting as the direct to film printing technique. This process, often referred to as UV direct-to-film printing, combines artistic creativity with advanced technology, enabling creators to design personalized items that stand out. From custom apparel to unique home decorations, the versatility of this approach opens up a realm of DIY crafting potential. By adopting these cutting-edge methods, hobbyists can easily produce high-quality designs that are both visually appealing and durable. Whether you’re looking to enhance your decor or start a bespoke clothing line, mastering this technique can truly elevate your creative projects.

Understanding UV DTF Printing Techniques

UV DTF printing techniques have gained significant traction in recent years thanks to their versatility and durability. This method allows creators to print stunning designs directly onto transfer films, which can then be applied to a wide variety of surfaces. The process involves using UV-curable inks that, once printed, undergo a curing process utilizing ultraviolet light. This ensures that the designs are not only vibrant but also incredibly resilient against scratching, fading, and weather damage.

Understanding the intricacies of the UV DTF printing process, from the initial design phase to the final curing step, is essential for achieving optimal results. Key aspects include selecting the right film and substrate, understanding the printer settings, and managing the curing environment, all of which can impact the final output of your project. By mastering these techniques, you can unlock endless possibilities for personalized home decor and custom apparel.

DIY UV DTF Printing: A Step-by-Step Guide

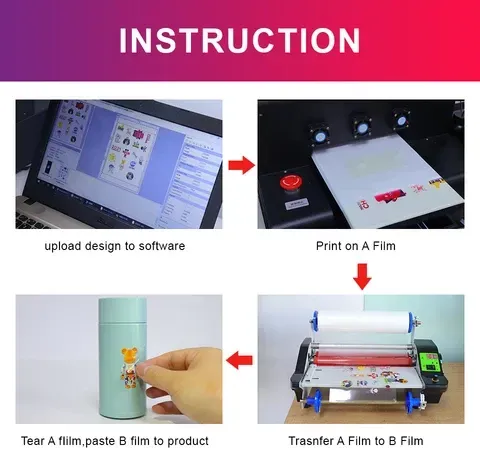

Embarking on a DIY UV DTF printing project can be a rewarding endeavor. To get started, gather the necessary materials: a UV printer, transfer film, and your chosen substrate. Begin by creating or selecting a design that you wish to print. Once you have your design ready, use the UV printer to print it onto the transfer film. It’s crucial to ensure that the printer settings are optimized for the type of film you are using to achieve the best results.

After printing, the next step involves carefully transferring the design onto your chosen substrate. Using a heat press, apply even heat and pressure to ensure a mated bond between the design and the substrate. Finally, expose the transfer to UV light for curing. This step solidifies the design and offers a lasting finish that holds up against everyday use. The entire process is fun and can lead to a multitude of creative projects, from apparel to personalized decor.

Benefits of DIY Crafting with UV DTF Printing

One of the most significant benefits of DIY crafting with UV DTF printing is the ability to personalize items uniquely. Whether creating custom apparel for events or designing unique home decorations, this printing method allows you to express creativity in ways that traditional printing may not. The durability of UV-cured inks also means the final products can withstand various conditions, making them perfect for both indoor and outdoor use.

Additionally, DIY UV DTF printing is becoming increasingly cost-effective due to reduced equipment prices and readily available materials. This trend allows hobbyists and small businesses to capitalize on the demand for personalized products at a reasonable cost. With the versatility offered by this printing method, creators are discovering new markets for custom items and unique gifts that were not previously accessible.

Experimenting with Different Substrates

When it comes to UV DTF printing, the choice of substrate can vastly influence the aesthetic and functionality of your craft projects. While commonly used materials include cotton, wood, and metal, the beauty of UV DTF printing lies in its ability to adhere to a plethora of surfaces. Experimenting with different substrates can lead to exciting textures and finishes that elevate your designs and provide unique opportunities for creative expression.

For instance, using a textured fabric can add depth to your designs, while trying out glass or acrylic can create stunning visual effects that catch the eye. Many DIY enthusiasts are exploring unconventional materials, such as ceramic tiles or even leather, to push the boundaries of traditional printing. This willingness to experiment not only enhances personal crafting projects but can also open new avenues in custom apparel and personalized home decor design.

Curing Techniques for Durable Outcomes

The curing process is critical in UV DTF printing and significantly affects the durability and quality of the final product. Proper UV curing ensures that the inks harden appropriately, providing a long-lasting finish that withstands wear and weather effects. It’s essential to use the right intensity and duration of UV light during the curing phase, which can prevent problems such as inadequate curing, leading to fading or peeling.

To ensure your designs endure through everyday use, consider experimenting with different curing techniques. Adjusting the distance of the UV light source from the substrate, the curing duration, and checking the manufacturer’s recommendations for optimal settings can make a dramatic difference. This attention to detail not only rewards you with higher-quality outcomes but also enhances the overall longevity of your custom prints.

Community Resources for UV DTF Enthusiasts

Becoming part of the vibrant community of UV DTF printing enthusiasts can greatly enrich your crafting journey. Online platforms, forums, and social media groups dedicated to this craft provide a wealth of information ranging from tutorials to troubleshooting advice. Engaging with fellow crafters allows you to stay updated on the latest techniques, tools, and trends in the DIY world.

Furthermore, many communities share project inspiration and unique design ideas, which can spark creativity for your next UV DTF project. Websites such as Instructables and Pinterest often feature innovative uses for UV printing, offering insights into successful crafting and product personalization. By connecting with like-minded individuals, you can enhance both your skills and enjoyment of DIY UV DTF printing.

Frequently Asked Questions

What materials can I use for DIY UV DTF printing?

DIY UV DTF printing is versatile and can be applied to a wide range of materials. You can print on fabrics, wood, metal, glass, and plastic. This flexibility allows you to create custom apparel, home decor, and promotional items, making it suitable for various DIY crafting projects.

How does the UV DTF printing process work?

The UV DTF printing process involves printing your design onto a special transfer film with a UV printer. After printing, the film is transferred to your chosen substrate using heat and pressure. Finally, UV light cures the inks, ensuring the designs are durable and weatherproof, perfect for lasting DIY creations.

What are the advantages of using UV DTF printing for custom apparel?

Choosing UV DTF printing for custom apparel offers significant advantages, such as vibrant colors and intricate designs that are durable and withstand frequent washing. The UV curing process provided by this technique ensures that your prints are scratch-resistant and weatherproof, making your apparel long-lasting and appealing.

Can I use UV DTF printing for personalized home decor?

Yes, UV DTF printing is ideal for creating personalized home decor items. You can craft beautiful wall art, custom signs, and unique decor pieces using various substrates. The durable finish of UV-printed designs ensures they maintain their vibrant appearance in your home.

What should I consider when selecting a UV printer for DIY projects?

When selecting a UV printer for DIY crafting, consider factors such as print quality, compatibility with various substrates, and user reviews. It’s also important to invest in a model that offers reliable durability and warranty options, as this will impact your overall experience with DIY UV DTF printing.

How can I ensure proper curing in my DIY UV DTF projects?

To ensure proper curing in your DIY UV DTF projects, position the UV light at the correct distance and use the appropriate intensity settings. Adequate exposure time is crucial for curing the inks effectively, preventing issues like fading or incomplete curing that can compromise your finished crafts.

| Key Point | Description |

|---|---|

| What is UV DTF Printing? | A technique that combines direct-to-film printing with UV curing for durable designs on various surfaces. |

| Key Steps | 1. Printing the design on transfer film. 2. Transferring the design using heat. 3. Curing with UV light to harden the ink. |

| Advantages | Versatile, durable, and cost-effective, making it suitable for crafting unique items. |

| Practical Tips | Invest in quality equipment, try different substrates, and ensure proper curing for best results. |

| Inspired Crafting Ideas | Custom apparel, home decor, and promotional items are among popular project ideas. |

| Community and Resources | Engage with online forums and craft blogs for support and inspiration. |

Summary

DIY UV DTF printing is an innovative technique that transforms how we approach crafting and product personalization. By understanding the core principles of this multifaceted printing method, enthusiasts can explore its diverse applications across various materials, from textiles to hard surfaces. This creative freedom, coupled with the durability achieved through UV curing, not only enhances the visual appeal of crafted items but also ensures they withstand daily wear. Embracing DIY UV DTF printing can lead to endless crafting possibilities, fostering a vibrant community of crafters who share insights and ideas. With the right techniques and tools, anyone can embark on an exciting crafting journey that pushes the boundaries of creativity.