The DTF Gangsheet Builder has emerged as a pivotal tool in the realm of Direct-to-Film (DTF) printing, enabling creators to simultaneously design and print multiple graphics on a single sheet with remarkable efficiency. This innovative approach not only streamlines the printing process but also significantly reduces material costs, making it a favorite among small business owners and professional print shops alike. As you dive into the world of DTF printing, mastering the techniques and strategies associated with a DTF Gangsheet Builder can lead to higher quality prints and enhanced operational efficiency. In this article, we will discuss essential DTF printing tips, gangsheet design techniques, and provide a comprehensive DTF printing tutorial to help you elevate your projects. Unlocking the full potential of your DTF Gangsheet Builder is key to achieving impressive results in your printing endeavors.

The DTF Gangsheet Builder is a game-changing resource for those engaged in Direct-to-Film transfer technology, enabling users to assemble multiple images on one film sheet efficiently. This consolidation method not only streamlines the printing workflow but also enhances cost-effectiveness in the production of intricate designs. In this guide, we’re diving into essential strategies and methodologies for effective gangsheet creation that align with best practices in DTF printing, ensuring optimal results every time. Whether you’re seeking innovative printing efficiency strategies or in-depth gangsheet design techniques, our analysis will equip you with the knowledge needed to thrive in the competitive landscape of fabric printing. By embracing these advanced techniques, you can maximize creativity while minimizing waste, ultimately driving your printing capabilities to new heights.

Mastering DTF Printing Techniques

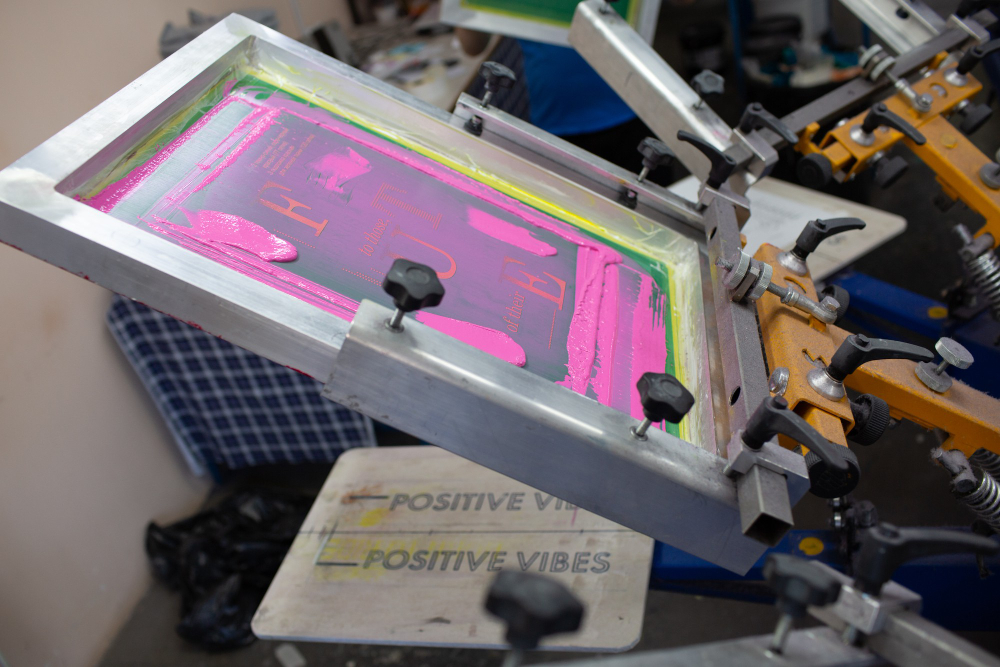

Understanding the nuances of Direct-to-Film (DTF) printing techniques is crucial for achieving high-quality results. Begin by focusing on the intricacies of preparing your digital designs, which include selecting suitable color profiles and ensuring that graphics scale properly for your intended materials. Mastering these tech specifics will enhance your capability in producing vibrant prints that stand out. Additionally, consider investing time in tutorials to learn about different DTF techniques like film handling and image processing, which can significantly contribute to your overall success.

Beyond just mastering the basics, experimenting with various DTF printing techniques can lead to unique and appealing design outcomes. This innovative spirit allows creatives to push boundaries and explore diverse themes or styles. Opt for a combination of direct and layered designs to enhance dimensionality and make prints even more captivating. These advanced techniques often yield results that not only impress customers but also increase operational efficiency as you find more effective ways to utilize your DTF Gangsheet Builder.

Essential Tips for Designing DTF Gangsheet Layouts

When utilizing the DTF Gangsheet Builder, optimizing your design layouts is pivotal for maximizing each printing session. Start with a clear plan on how to arrange your graphics; overlapping designs and placing them strategically can significantly reduce waste. The key is to create a balanced layout that utilizes the entire sheet without compromising on the quality of each design. Remember, utilizing negative space wisely in your layouts can lead to more visually appealing results and save material costs in the long run.

Further, color management within your gangsheet layout should not be overlooked. Ensure each design maintains consistency across the printing sheet by checking color profiles beforehand. Using tools to calibrate displays and test printing on various fabric samples can help identify potential color discrepancies early in the process. Teaching yourself these layout strategies will not only boost productivity but also refine your artworks, giving your DTF prints the professional edge they deserve.

Choosing the Best Materials for DTF Printing

The selection of materials for DTF printing is integral to achieving durable and vibrant end products. High-quality DTF films and inks specifically formulated for the process are crucial; they ensure adequate adhesion and longevity of the prints on various fabrics. Research the compatibility of different materials with your printer and inks; this knowledge will allow you to avoid substandard results that diminish the quality and satisfaction of your finished products.

Additionally, when pursuing optimal results in DTF printing, consider experimenting with various film thicknesses and finish types. Glossy finishes might enrich colors, while matte options can provide a sophisticated touch. Each choice impacts the design’s feel and durability, and understanding these materials further enables you to cater to specific customer needs, enhancing satisfaction and loyalty.

Optimizing DTF Printer Settings for Quality Results

Achieving optimal printing results with your DTF printer requires a solid understanding of your machine’s settings. Take the time to familiarize yourself with various settings, including ink saturation, resolution, and print speed, as these factors directly influence print clarity and vibrancy. Regularly tweaking these parameters according to the design complexity and substrate can lead to outstanding printing results that exceed client expectations.

In addition, don’t shy away from conducting test runs when introducing new materials or designs. This practice allows you to pinpoint the best combinations of settings before the final print run, saving resources and time. Keeping a log of your successful settings for various projects can streamline future efforts and significantly improve your overall printing efficiency, ensuring continued satisfaction in your DTF printing endeavors.

Heat Press Techniques for Successful DTF Transfers

One of the most vital phases in the DTF process is the heat transfer of designs onto fabrics. Understanding and applying the correct heat press techniques can make or break the quality of your printed products. Key parameters such as temperature, pressure, and transfer duration must be meticulously calibrated according to your specific fabric types and ink formulations. Improper settings can lead to incomplete transfers or designs that simply don’t adhere properly to the fabric.

To ensure successful transfers, it’s advisable to conduct preliminary tests on scrap fabrics. This initial testing allows for adjustments to be made in a controlled environment before proceeding to final products, ensuring prints not only adhere securely but also retain quality under varied washing and wear conditions. By refining your approach to heat application, you can achieve impeccable results that resonate with your customer base.

Aftercare for DTF Printed Fabrics

Post-printing care is just as essential as the printing process itself when it comes to Direct-to-Film outputs. Educating clients on the proper washing and maintenance of DTF-printed fabrics can significantly extend the lifespan of your products. Recommend cold washing and air drying techniques to maintain the vibrancy and adhesion of printed graphics, which ensures your clients remain satisfied with their purchases for years to come.

Moreover, consider providing informative guides on care instructions with each order. A simple care label or brochure detailing optimal handling practices helps set customer expectations and minimizes potential future complaints regarding print quality. Demonstrating expertise in aftercare not only boosts your reputation but can also lead to repeat business, as satisfied customers are more likely to return for future projects.

Frequently Asked Questions

What is DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for Direct-to-Film (DTF) printing that allows users to arrange multiple designs onto a single film sheet. This maximizes material usage while minimizing costs, making the printing process more efficient.

What are some essential DTF printing tips for using a Gangsheet Builder?

To effectively use a DTF Gangsheet Builder, ensure your designs are appropriately sized and strategically placed to maximize space. Optimizing color management and familiarizing yourself with design software are also crucial tips for improving your printing quality.

How do printing settings affect DTF Gangsheet Builder outcomes?

Optimizing your printer settings is critical for DTF Gangsheet performance. Each design may require different adjustments in resolution and ink saturation, which dramatically influence the quality of your print outcomes.

What role does material selection play in the effectiveness of a DTF Gangsheet Builder?

Choosing the right materials, such as high-quality DTF films and compatible inks, directly impacts print adhesion and longevity. Using subpar materials can lead to prints that wear out quickly or peel off easily.

Can you recommend any resources for learning DTF printing techniques related to Gangsheet Builders?

Yes! Workshops and tutorials available on YouTube, as well as engaging in online communities, can be extremely helpful in mastering DTF printing techniques and staying updated on the latest trends.

What are best practices for applying prints from a DTF Gangsheet?

Proper heat pressing techniques are vital for transferring designs successfully. Ensure to set the correct temperatures, pressure, and timing, and always test these parameters on scrap fabrics before applying to your final products.

| Tips and Tricks | Details |

|---|---|

| Design Optimization | Involves size and placement for efficiency, color management using RGB profiles, and test prints for accuracy. |

| Software Proficiency | Familiarity with design software like Adobe Photoshop; use of templates can enhance workflows. |

| Material Selection | Choosing high-quality DTF films and inks ensures better adhesion and longevity of prints. |

| Printing Settings | Optimize printer settings according to design complexity; adjust resolution and ink saturation. |

| Application Techniques | Ensure proper heat press settings (temperature, pressure, timing) to achieve successful transfers. |

| Post-Printing Care | Educate users on washing and care practices to maintain prints’ vibrancy and longevity. |

Summary

DTF Gangsheet Builder is an essential tool in the textile printing industry that allows users to maximize design efficiency while minimizing material costs. By implementing strategic design optimization techniques, mastering relevant software, ensuring the use of quality materials, fine-tuning printing settings, and practicing proper application techniques, users can significantly improve their printing outcomes. Additionally, educating clients on post-printing care is vital for maintaining print quality over time. Embrace these strategies to stay competitive in the evolving world of DTF printing and deliver impressive, durable products that keep customers satisfied.