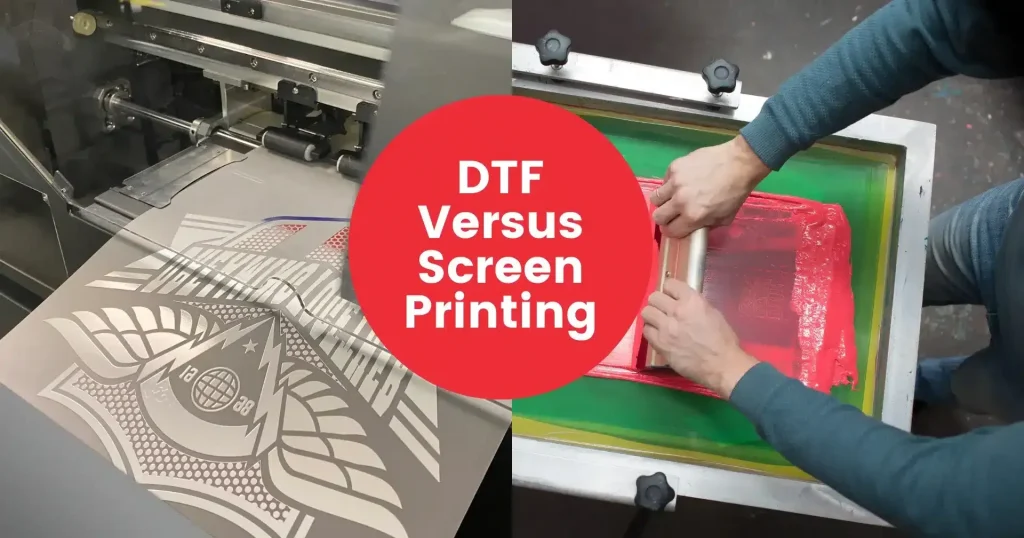

DTF vs Screen Printing is a common choice facing apparel brands, designers, and makers who want durable prints that pop across a range of fabrics. Understanding the strengths and tradeoffs of these approaches helps you align artwork, production timelines, and budget with real-world outcomes across diverse product lines and markets. DTF supplies play a role in flexibility and speed, while fabric printing methods influence how textures and color respond on cotton, blends, and synthetics. For projects with complex gradients or full-color photography, DTF offers high fidelity, whereas screen printing excels with bold solids and scalable per-unit costs as volume grows, especially when orders cycle through seasonal designs. If you’re unsure where to start, this comparison helps identify quick wins, such as when to prioritize short runs, underlays, or swapping techniques to match fabric, design, and delivery needs, and it equips teams to test, quote, and plan with confidence for teams planning production schedules.

From a terminology perspective, the conversation often shifts from Direct-to-Film transfers to film-based transfer methods, and from silk-screen to screen-printing techniques. This framing emphasizes how color replication, texture, and fabric compatibility are handled in different workflows. Using terms like direct-to-film transfer and silk-screen printing helps builders and buyers connect with resources, guides, and suppliers without getting hung up on acronyms. By adopting varied language around these processes, readers can navigate decisions about equipment needs, ink options, and durability expectations more confidently.

1. DTF vs Screen Printing: Core Differences Explained

DTF vs Screen Printing represents two distinct pathways for apparel decoration, each with its own strengths in image handling, color fidelity, and workflow. DTF printing vs screen printing tends to excel in different design scenarios: DTF shines with multi-color artwork, gradients, and photorealistic detail, while traditional screen printing delivers bold, solid colors with clean edges. Understanding these core differences helps you map your artwork to the most efficient method, saving time and materials while maintaining print quality.

In practice, the choice often comes down to design complexity, color count, and production speed. DTF supplies and a well-tuned transfer process enable rapid prototyping and small-batch runs, whereas screen printing becomes increasingly economical as volume grows and the design relies on fewer color separations. By evaluating your artwork against these tendencies, you can gauge which method aligns with your project’s timeline, fabric choices, and brand goals.

2. DTF Supplies: What You Need to Start

To begin with DTF, you’ll assemble a kit of DTF supplies that supports reliable transfers across a range of fabrics. Typical components include DTF films and pre-printed transfer sheets, heat-activated adhesive powders, PET-based transfer films, curing equipment, and quality heat presses. Having dependable DTF supplies ensures consistent color transfer, adhesion, and durability right from the first tests.

As you scale, focus on sourcing compatible films, powders, and curing equipment from reputable providers to minimize voids and failures in production. The right DTF supplies not only improve print quality but also reduce downtime between runs, enabling faster iteration when testing new designs or colorways for your garment line.

3. Screen Printing Costs and Setup: What to Budget For

Screen printing costs encompass more than the price of ink. In a traditional setup, you’ll consider emulsion costs, screen creation and maintenance for each color layer, ink and curing equipment, and the labor required for multi-color separations and color matching. Recognizing these line items helps forecast the true cost per garment, especially when evaluating long runs and color-heavy designs.

While upfront investment in screens and setup can be substantial, the per-unit cost typically drops as volume increases—making screen printing highly cost-efficient for large orders with simple color schemes. This cost curve is a key factor when deciding between DTF and screen printing, particularly for designs that can be streamlined into a few solid colors or simple separations.

4. Fabric Printing Methods: How DTF and Screen Compare Across Materials

Fabric printing methods differ in their interaction with various textiles, and both DTF and screen printing have fabric-specific strengths. DTF transfers tend to perform well on cotton blends, poly blends, and fabrics that are harder to print with traditional inks, while screen printing works across a broad fabric range but may require underbases for difficult materials or dark fabrics.

Choosing between these methods for a given fabric involves testing for wash durability, color density, and hand feel. DTF can offer a lighter hand and vibrant color on diverse fabrics when properly executed, whereas screen printing may deliver a robust ink layer and long-term stability on typical apparel fabrics, especially at scale.

5. How to Choose Between DTF and Screen Printing for Your Run

How to choose between DTF and screen printing hinges on run size, design complexity, and fabric variety. For small runs with multiple colors and gradients, DTF printing vs screen printing often provides faster turnaround and easier design variation. If your project includes high-volume orders with simple color palettes, screen printing can deliver lower per-unit costs and a streamlined workflow.

Considerations such as base fabric, desired finish, and production speed also influence the decision. If you’re evaluating pros and cons, outlining a quick decision checklist—run size, color count, fabric type, and budget—can clarify which method offers better value for your specific needs.

6. Hybrid Approaches: Prototyping with DTF and Scaling with Screen Printing

A practical strategy is to prototype designs with DTF supplies to validate artwork, color fidelity, and fit before committing to large-scale production. This approach leverages the agility of DTF printing vs screen printing for quick proofing, color testing, and design refinements without heavy upfront investments.

Once a design is finalized, many brands pivot to screen printing to capitalize on long-run efficiency and predictable costs. A hybrid workflow—DTF for prototyping and small runs, then scaling with screen printing for steady, high-volume production—can optimize margins, turnaround times, and the breadth of your catalog while staying aligned with how to choose between DTF and screen printing.

Frequently Asked Questions

DTF vs Screen Printing: Is this a good fit for small runs, and what DTF supplies should I have on hand?

DTF vs Screen Printing is often favorable for small runs because DTF requires less upfront setup and offers quick design changes, while screen printing’s per-unit cost drops with higher volumes. For DTF projects, essential supplies include DTF films and pre-printed transfer sheets, heat-activated adhesive powders, PET transfer films, curing equipment, and a reliable heat press. This setup enables fast prototyping, good color fidelity on many fabrics, and short lead times.

DTF printing vs screen printing: how do costs compare as you scale production?

DTF printing tends to have lower setup costs, making it cost-effective for small runs, while screen printing becomes more economical per unit at larger volumes due to shared screens and ink usage. Screen printing costs include setup for each color, screens or stencils, inks, emulsions, and curing equipment.

Which fabric printing methods are best for complex color designs: DTF vs screen printing?

DTF printing excels with complex color, gradients, and photo-like artwork, making it a strong option among fabric printing methods for multicolor designs. Screen printing is ideal for bold, solid colors and simpler color counts, delivering cost-efficient performance at scale.

How to choose between DTF and screen printing for your project?

Consider design complexity, run size, fabric type, turnaround time, and budget. If you need quick proofs and multicolor detail with small runs, DTF supplies and transfers are favorable. For large-volume orders with limited colors and high throughput, screen printing offers the best per-unit cost and proven durability.

What factors affect durability and washability when comparing DTF vs screen printing?

Durability depends on ink type, adhesion, curing, and post-treatment. DTF transfers rely on adhesive powders and film adhesion; screen printing relies on ink curing and screen integrity. Proper curing times, fabric compatibility, and post-care practices influence wash durability for both methods.

Should you test with DTF supplies before scaling to screen printing, or consider a hybrid approach?

Yes. Use DTF supplies for rapid prototyping and on-demand variations to validate artwork and color fidelity. Once you’re ready for large volumes, switch to screen printing for efficiency and consistent color at scale. A hybrid approach—prototype with DTF, then fulfill high-volume core products with screen printing—can maximize flexibility and margins.

| Aspect | DTF (Direct-to-Film) Key Points | Screen Printing Key Points | Notes / When to Choose | |

|---|---|---|---|---|

| Image quality & color handling | DTF excels with complex, multi-color designs, gradients, and photo-like images; strong color fidelity on dark fabrics | Screen printing shines with bold, solid colors and clean edges; fewer color layers | Choose based on design complexity and color count; use DTF for multi-color artwork, screen for simpler designs at scale. | |

| Fabric compatibility | DTF is versatile on cotton blends, poly blends, and fabrics harder to print with traditional inks | Screen printing covers a broad fabric range, but may need underbases or special inks for poly/dark fabrics | Consider fabric type and color base when selecting method; test on fabrics to confirm performance. | |

| Durability & feel | DTF transfers can be durable with proper curing; hand feel can be lighter with quality materials | Screen printing inks can feel thicker but offer strong durability when cured | Expect differences in hand feel and wash performance; ensure proper curing and material quality. | |

| Cost & volume | Lower setup for small runs; economical for short runs and multi-design projects | Per-unit cost drops with volume; high upfront investment in screens; efficient for large runs | DTF favors small runs and design variation; Screen favors high volumes and simpler color schemes. | |

| Turnaround & flexibility | Faster prototyping; no new screens for variations; quick proofs | Upfront setup longer; once screens exist, production can be very fast at scale | DTF is ideal for rapid changes and proofs; Screen is best for steady, high-volume production. | |

| Environmental & safety considerations | Adhesives and heat-activated powders; handle powders; ensure safe handling | Inks, solvents, and curing require ventilation and waste management | Both methods need proper controls and safety practices for sustainable use. | |

| Upfront costs & equipment | Heat press, DTF films and powders, desktop/inkjet printer; ongoing film/powder costs | Screens, emulsions, inks, curing equipment; larger initial investment | Budget for equipment and consumables; DTF may have lower entry costs for small shops; Screen requires scale to break even. | |

| Ideal users | Small businesses, designers testing colorways, print-on-demand, complex color detail | Large-volume orders, limited color palettes, long-run efficiency | Match method to business model: DTF for flexibility and rapid testing; Screen for scale and consistency. | |

| Practical considerations & decision checklist | Run size, design complexity, fabric, turnaround, budget; prioritize rapid proofs when using DTF | Run size, color separations, fabric, turnaround; plan for repeatable high-volume runs | Use a quick checklist to decide: size, complexity, fabric, budget, turnaround; consider testing both methods. | |

| Hybrid approach & coexistence | Prototype with DTF to validate artwork quickly; scale to screen for large-volume orders | Use screen for baseline products; reserve DTF for on-demand or complex designs | Hybrid strategies can optimize margins, turnaround, and catalog breadth. | |

| Case studies & practical examples | Case A: eight micro-collections/year, 150–300 shirts per collection; rapid, full-color artwork with DTF | Case B: 2,000 shirts/month with two-color logo on solid fabrics; screen printing offers unit-cost efficiency | Case C: custom orders with varying designs; DTF offers flexibility and reduced waste from unused screens |

Summary

DTF vs Screen Printing is a strategic choice influenced by design, volume, fabric, and brand goals. This overview highlights how DTF offers speed, versatility, and vibrant full-color reproduction for complex artwork and smaller runs, while screen printing delivers cost efficiency and durable performance at scale for high-volume orders. By aligning the method with your product line and production needs, you can optimize quality, turnaround, and margins across your apparel line.