UV DTF printing is revolutionizing the printing industry by merging the speed of direct-to-film techniques with the durability of UV curing. This innovative process allows artists and manufacturers to produce vibrant, high-quality graphics on a diverse array of materials, from textiles to metals. The benefits of UV DTF printing are evident, as it not only maximizes versatility across different substrates but also supports the current trend toward customization in products. As businesses increasingly seek personalized promotional items and creative applications of UV DTF, the market continues to expand. By adopting this state-of-the-art UV DTF technology, companies can enhance their competitive edge and satisfy their customers’ evolving demands.

Often referred to as ultraviolet direct-to-film printing, this cutting-edge printing method is transforming the landscape of digital design. By seamlessly blending direct printing techniques with specialized UV inks, this technology allows for rich, intricate designs that can be applied to a vast selection of surfaces. Many industries are now exploring the emerging UV printing trends, which enhance product customization and personalization, meeting the rising consumer desire for unique items. The growing adoption of this innovative printing solution not only amplifies artistic creativity but also aligns with more sustainable practices. As UV DTF continues to gain traction, its potential applications in producing custom products and promotional materials are endless.

Understanding the Mechanics of UV DTF Technology

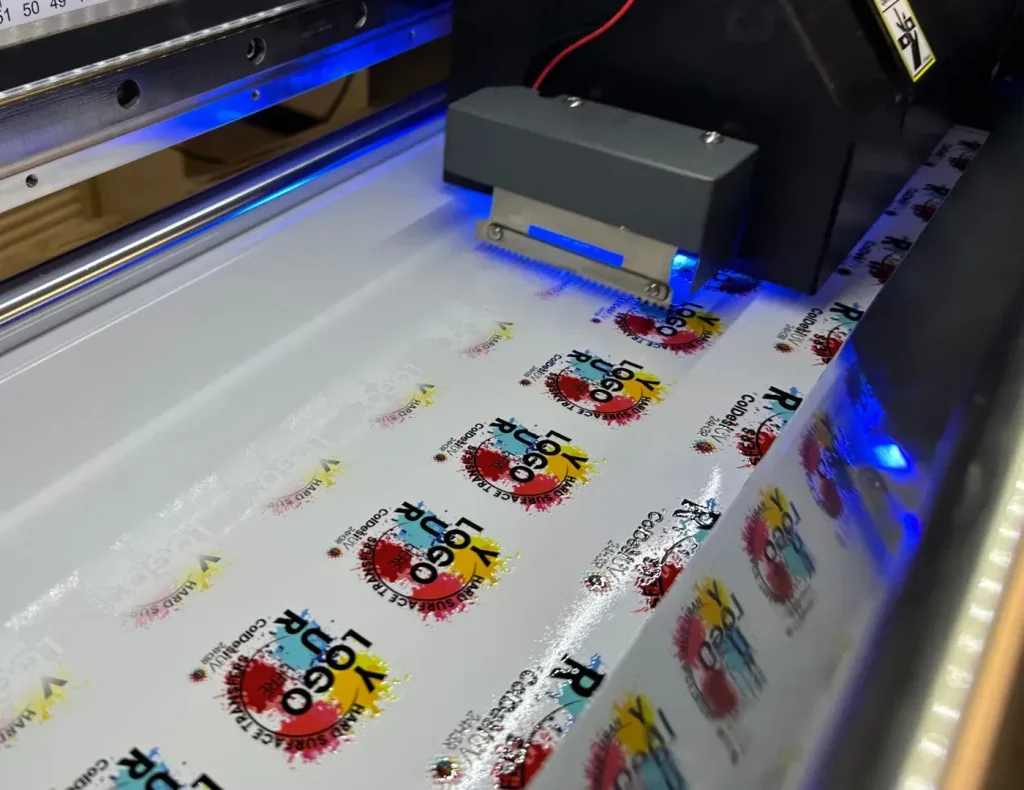

At its core, UV DTF technology merges two advanced printing methods: direct-to-film and ultraviolet curing. This combination allows for vibrant, high-resolution prints that adhere well to a wide range of substrates. With traditional printing systems often constrained by the type of materials they can effectively print on, UV DTF liberates creativity by enabling designs to be applied to textiles, plastics, metal, and wood. This versatility is particularly beneficial in industries such as fashion and advertising, where brand visibility and customization options are paramount.

Moreover, the UV DTF printing process employs inks that cure instantly under UV light, facilitating swift production turnaround times. This not only enhances productivity for businesses but also allows designers to experiment with intricate patterns and color combinations, resulting in unique products that stand out in a competitive marketplace. As such, understanding the mechanics of UV DTF is essential for individuals and businesses looking to leverage this innovative technology effectively.

Creative Applications of UV DTF Printing

UV DTF printing offers a multitude of creative applications that cater to diverse industries and artistic endeavors. For example, fashion designers can utilize this technology to produce unique apparel pieces with elaborate prints that capture their brand’s identity. This capability not only differentiates their offerings but also resonates well with consumers looking for personalized and one-of-a-kind products.

Additionally, promotional companies are increasingly adopting UV DTF printing to create custom merchandise, from promotional gifts to branded packaging. The ability to print on various materials means that companies can experiment with different textures and finishes, thus enhancing the overall appeal of their products. Whether creating dynamic visuals for marketing or offering distinctive items for personal use, the creative applications of UV DTF printing are practically limitless.

Further illustrating this trend, businesses specializing in home decor are also tapping into UV DTF technology, allowing customers to personalize items like wall art and furniture. This shift reflects a broader movement towards customization in consumer goods, where buyers seek to express their individuality through bespoke products.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing refers to UV Direct to Film printing, a cutting-edge method that combines direct-to-film capabilities with UV curing technology. This innovative process allows for the application of high-quality graphics on various substrates, such as textiles, plastics, and metals, making it a versatile option for custom products.

What are the benefits of UV DTF printing for businesses?

The benefits of UV DTF printing include exceptional versatility, enabling printing on a wide range of materials, rapid production speeds that enhance efficiency, and environmentally friendly practices, thanks to lower VOC emissions from UV inks. These advantages position businesses to meet customer demands quickly while maintaining high-quality standards.

What creative applications can be achieved using UV DTF technology?

Creative applications of UV DTF technology are vast, spanning custom apparel, promotional products, and unique home decor items. The technology’s capability for vibrant color reproduction and intricate designs allows artists and manufacturers to explore endless creative possibilities.

How is UV DTF printing evolving with industry trends?

Current trends in UV DTF printing include a growing demand for personalization and customization, driven by e-commerce. Additionally, advancements in design software and digital tools are enhancing the use of UV DTF technology, allowing designers to push creative boundaries further.

What are the latest trends in UV DTF printing?

UV DTF printing trends highlight the rise in investment from companies looking to expand their printing capabilities and the shift towards sustainable practices. Personalization is also a key trend, as businesses leverage UV DTF technology to create customized products that cater to individual customer preferences.

How does UV DTF printing support sustainable practices?

The environmental benefits of UV DTF printing include a reduction in volatile organic compounds (VOCs) compared to traditional inks, making it a more sustainable printing option. This aligns with current industry shifts towards eco-friendliness while still delivering high-quality results.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A revolutionary digital printing method combining direct printing capabilities with UV curing, allowing high-quality graphics on various surfaces. |

| Advantages | Includes versatility, speed and efficiency, and environmental benefits due to reduced VOCs. |

| Emerging Trends | Customization and personalization, use of advanced digital technologies, and increased investments in UV DTF tech. |

| Real-World Applications | Used in custom apparel, promotional items, and various other industries, showcasing its adaptable nature. |

Summary

UV DTF printing represents a revolutionary advancement in the printing industry, merging creativity with technology for remarkable results. Through its versatile applications, UV DTF printing pushes the boundaries of design, allowing for high-quality graphics on a wide array of materials. Its ability to deliver fast, customizable outputs not only meets the growing demand for personalized products but also supports sustainability initiatives with its lower environmental impact. As more businesses adopt UV DTF technology, the potential for unique, impactful printing solutions continues to expand, highlighting its significance in the evolving landscape of modern printing.